Radiation-cooled Systems

Ultramet manufactures five radiation-cooled chambers:

- Iridium/rhenium

- Oxide-iridium/rhenium

- Iridium/rhenium-carbon/carbon

- Oxide-iridium/rhenium-carbon/carbon

- Ceramic matrix composite

Iridium/Rhenium Chambers

Ultramet’s flagship product, the iridium/rhenium combustion chamber (patent 4,917,968), first flew in 1998 and enjoys a 100% success rate. Primarily used in missions to insert satellites into geosynchronous orbit, these chambers operate at temperatures up to 3992°F (2200°C) and provide a 10- to 20-second increase in specific impulse over conventional chamber materials.

Iridium/rhenium combustion chamber, patented by Ultramet, and niobium sleeve attachments as part of a liquid apogee engine

Ultramet coats the exterior of the rhenium chamber with a black rhenium coating to provide an emittance of nearly 1.00 that results in enhanced radiation cooling. On each end, niobium flanges, manufactured at Ultramet by chemical vapor deposition, simplify attachment to the injector and the exhaust cone.

The iridium/rhenium chamber is state-of-the-art for NTO/MMH and NTO/N2H4 propellant systems. Since the mid 1990s, Ultramet has sold an average of nearly 10 iridium/rhenium chambers each year for satellite integration and flight, and demand is increasing. These high-performance engines save fuel and expand the possibilities for mission planners. Some missions would not have been possible without the performance offered by Ultramet’s iridium/rhenium chambers.

Oxide-Iridium/Rhenium Chambers

Ultrahigh temperature version of iridium/rhenium chamber

Oxide-iridium/rhenium chamber

The oxide-iridium/rhenium chamber was developed for ultrahigh temperature applications. Targeted for radiation-cooled use with stoichiometric oxygen/hydrogen, these chambers have demonstrated hours of life at temperatures of 4352°F (2400°C) and the ability to endure many minutes of steady-state operation with wall temperatures of 4892°F (2700°C), the highest temperature at which any material system has ever been tested. The Air Force is investigating this material system for use with HAN-based monopropellants.

Iridium/Rhenium-Carbon/Carbon Chambers

Lightweight version of iridium/rhenium chamber

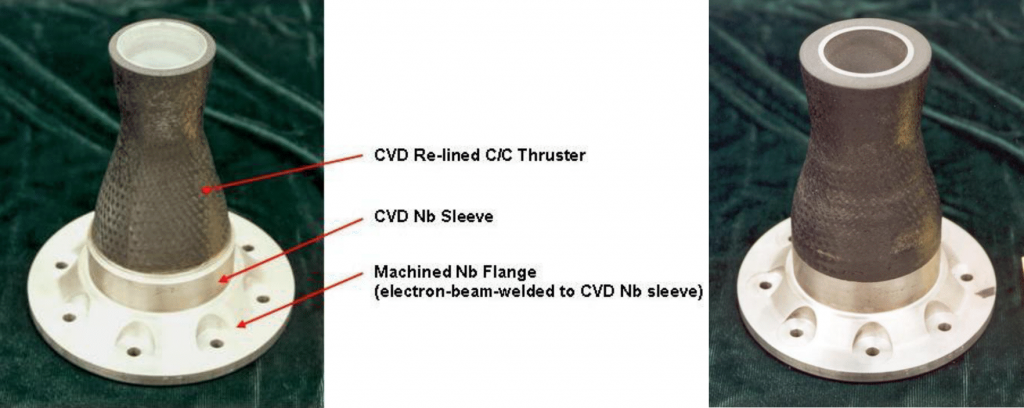

Iridium/rhenium-carbon/carbon chamber with niobium injector flange

To avoid the weight penalty associated with a large iridium/rhenium chamber, Ultramet replaces most of the rhenium with low-density carbon/carbon. The result is a lightweight, high-performance engine that can operate at high temperature and at high pressure. Iridium/rhenium-carbon/carbon chambers have been successfully hot-fire tested with oxygen/hydrogen and NTO/MMH.

Oxide-Iridium/Rhenium-Carbon/Carbon Chambers

Lightweight version of oxide-iridium/rhenium chamber

Originally developed for use as part of a Mars sample return mission, the oxide-iridium/rhenium-carbon/carbon engine offers the performance of oxide iridium/rhenium at a fraction of the weight. By replacing most of the structural rhenium with low-density carbon/carbon, significant mass savings are achieved without compromising structural integrity. As chamber size increases, so do the mass savings.

Ceramic Matrix Composite Chambers

Carbon Fiber-Reinforced Silicon Carbide

The high temperature corrosion resistance and oxidation resistance of silicon carbide are combined with the strength and toughness of carbon fibers.

Carbon Fiber-Reinforced Zirconium Carbide

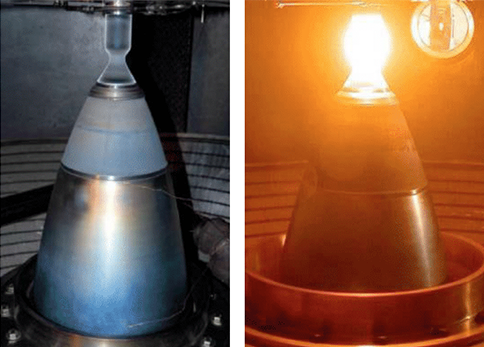

Ultramet carbon fiber-reinforced zirconium carbide combustion chamber during 4350ºF (2400ºC) hot-fire testing at NASA Glenn

Regeneratively Cooled Systems

By using the unique flow distributing properties of rhenium foam, regeneratively cooled combustion chambers can be made at a fraction of the cost of traditional brazed tube chambers. Ultramet’s regeneratively cooled chambers have been successfully hot-fire tested with oxygen/hydrogen propellants and represent the next step in high-thrust rocket engines.

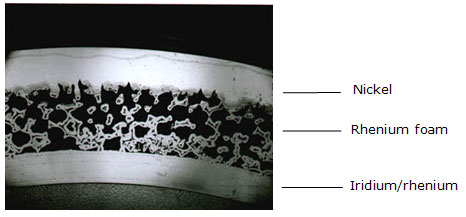

Cross-section of regeneratively cooled foam core combustion chamber showing rhenium foam through which fuel flows

Advantages

- Turbulent flow created by the foam coolant channel, combined with a relatively low pressure drop, allows heat fluxes that are five times greater (up to 22.36 MW/m2) than those of conventional open coolant channels.

- The structural foam core is simple to manufacture and requires no complex or expensive machining of intricate passages.

- Foam exhibits high specific stiffness, thereby minimizing weight.

- Foam can be fabricated from various metal and ceramic materials.

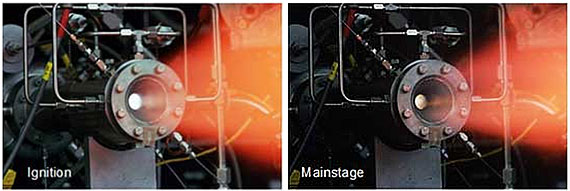

Hot-fire testing of Ultramet regeneratively cooled foam core combustion chamber with oxygen/hydrogen at the Mohave Test Area (Mojave, CA)

Transpiration-cooled Systems

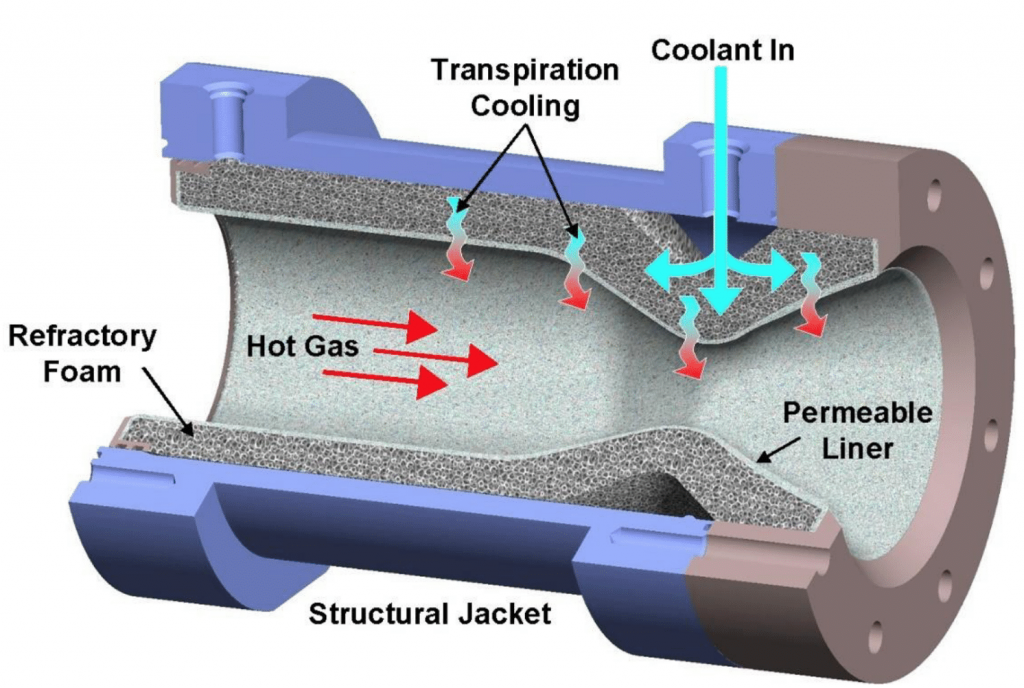

Available in metallic or ceramic forms, Ultramet’s transpiration-cooled combustion chambers increase performance and reduce cost. By allowing a small portion of the fuel to flow directly through the wall, wall temperatures are kept low, and oxidation of the chamber wall is virtually eliminated.

Advantages

- A foam core transpiration-cooled engine offers all the advantages of a foam core regeneratively cooled engine plus the following:

- Increased coolant flow can be easily directed at areas subjected to the greatest heat flux;

- The inner wall of the entire chamber is maintained under nonoxidizing conditions, thus eliminating concern about oxidation;

- The need for fuel-film cooling is eliminated, which simplifies the injector design;

- Because only 2–5% of the total fuel flow is needed for transpiration and because no fuel-film cooling is needed, most of the fuel can be used for combustion and burned efficiently;

- The lower coolant volume reduces cost and weight associated with turbomachinery.

In transpiration cooling, an open-cell structural foam is combined with a fine porosity liner at the inner surface with tailorable permeability. Only 2% of the total fuel flow is required for cooling.

Open-cell 80-ppi molybdenum foam with 0.030″ porous molybdenum liner used in transpiration-cooled combustion chambers. Left, unpolished (10×); right, polished (40×).

Transpiration-cooled molybdenum foam/porous molybdenum liner combustion chamber during oxygen/hydrogen hot-fire testing at NASA Glenn

Chambers for High-Performance Propellants

Ultramet has manufactured and successfully hot-fire tested chambers with exotic, high-performance propellants such as stoichiometric oxygen/hydrogen and fluorine/hydrazine:

- Stoichiometric oxygen/hydrogen (O2/H2)

Isp = 444 seconds

Tflame = 6170°F (3410°C)

- Fluorine/hydrazine (F2/N2H4)

Isp = 430 seconds

Tflame = 8074°F (4468°C)

Chambers used with these propellants have survived hot-fire tests for thousands of seconds and used only radiation cooling. Regardless of the propellants, Ultramet can devise a material system to meet your needs.

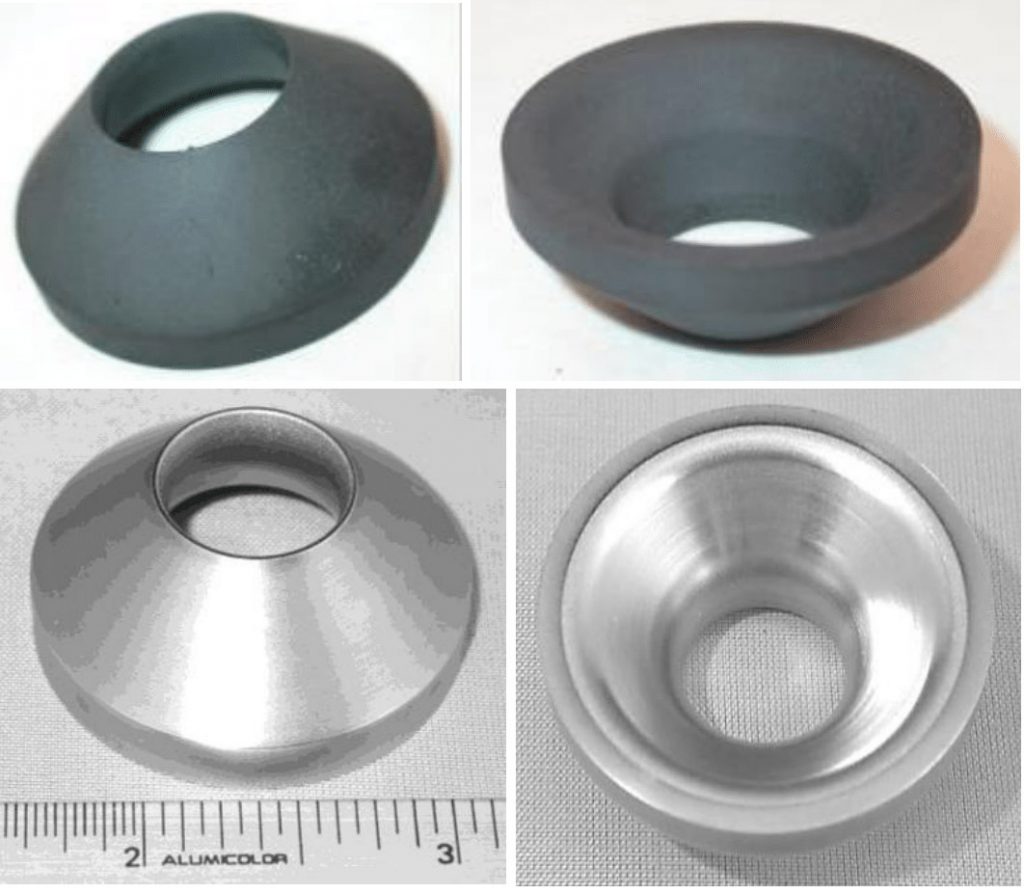

Rhenium-lined Graphite and Carbon/Carbon Pintles and Throats

Rhenium-lined graphite and carbon/carbon structures provide the proven benefits of flight-qualified CVD rhenium at substantially reduced weight and cost.

Graphite pintle before (top) and after (bottom) CVD rhenium coating

Graphite throat before (top) and after (bottom) CVD rhenium coating