Ceramic Protective Coatings

Ultramet applies protective coatings to carbon/carbon and ceramic matrix composites, graphite, refractory metals, and superalloys for operation in severe environments. Low temperature deposition (<752°F [400°C]) is possible to accommodate components with low melting points.

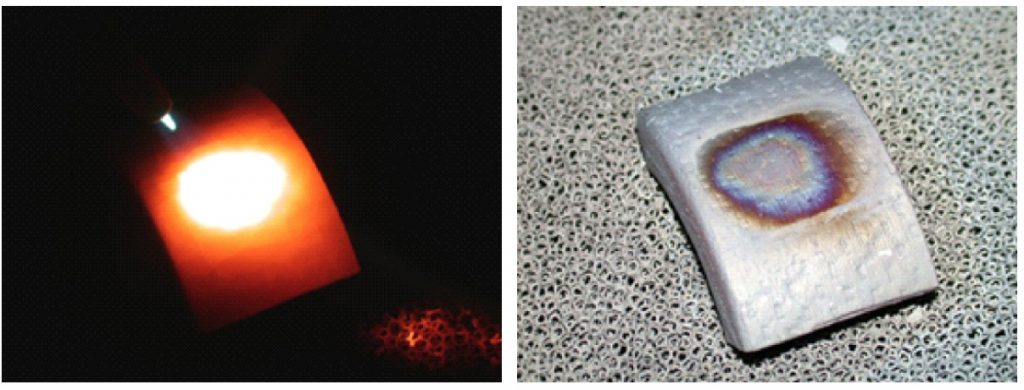

Photographs of carbon/carbon coupon coated with layered hafnium carbide/silicon carbide during and after oxyacetylene torch testing

Advantages of Ceramic Protective Coatings

- High temperature oxidation protection for refractory metal-, ceramic-, and carbon-based components

- Deposition at temperatures as low as 10% of the melting point of the coating material

- No porosity (fully dense)

- Availability in various metal carbides, oxides, nitrides, and borides

- High emissivity

- Thermal protection

- Applicability to intricate shapes and textured surfaces

Applications of Ceramic Protective Coatings

- Engine and airframe components

- Fiber interface coatings

- Thermal protection system components