Kaplan-Ultramet Award in Biological Physics

The Center for Biological Physics at UCLA gratefully acknowledges an endowment provided by Richard Kaplan, a UCLA physics alumnus (MS 1962) and founder of the research and development company Ultramet. Thanks to this generous award, the Center will be able to offer the Kaplan Ultramet Award in Biological Physics, beginning in Fall 2014, to a deserving graduate and undergraduate student each year. This award will not only help support student research at UCLA, it will also provide new opportunities for promising students to broaden their study of physics by attending international research institutes, participating in conferences, and visiting collaborators world-wide. Read more

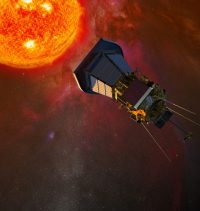

The Parker Solar Probe

NASA’s Parker Solar Probe will be the first-ever mission to “touch” the Sun. The spacecraft, about the size of a small car, will travel directly into the Sun’s atmosphere about 4 million miles from our star’s surface. The Parker Solar Probe officially launched on August 12, 2018 at 3:31 a.m. EDT (7:31 UTC).

Explore how Ultramet helped design and manufacture a revolutionary heat shield able to withstand extreme heat. Read More

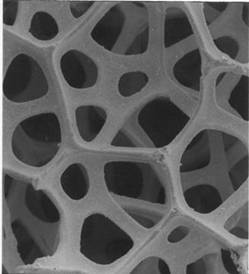

Ceramic Industry

Ultramet’s work in melt infiltration of refractory ceramic matrix composites (CMCs) is featured in the August 2014 issue of Ceramic Industry.

Refractory CMCs are of considerable interest for a range of high temperature and severe environment applications. Ultramet’s melt infiltration process promotes rapid, cost-effective fabrication of CMCs.

Standard Missile-3

For more than a decade Ultramet manufactured rhenium components for the solid divert and attitude control system of the Standard Missile-3 (SM-3), Block IA, the Navy’s mobile ballistic intercept system.

On February 20, 2008, the Navy used the SM-3 to intercept a broken spy satellite and explode the satellite’s tank carrying toxic hydrazine rocket fuel. Right, launch of SM-3 from USS Lake Erie (CG 70) on February 20, 2008.

Personal Air Vehicle

Ultramet’s open-cell ceramic foam was an enabling technology for a modified RV-4 aircraft that won the $50,000 Noise Prize in the 2007 CAFE Foundation’s NASA Personal Air Vehicle Centennial Challenge on August 11, 2007, in Santa Rosa, California. The muffler on the RV-4 was lined with Ultramet’s silicon carbide foam broadband sound absorber and was built using Ultramet’s assembly techniques. While flying at 192 mph, the aircraft operated at a noise level three times quieter than that of most small aircraft.

AFRL

Ultramet’s work in advancing structural thermal protection systems, particularly for the scramjet, is included in the 2007 edition of AFRL Technology Milestones.

Published annually by the Air Force Research Laboratory (AFRL) at Wright-Patterson Air Force Base (Ohio), AFRL Technology Milestones is used by AFRL to inform leadership and the general public of significant technology advances and revolutionary developments in the Air Force research program

NASA has included four Ultramet SBIR programs among its

NASA has included four Ultramet SBIR programs among its

SBIR/STTR Success Stories:

Fiber-Reinforced Ceramic Matrix Composites for High-Temperature Environments

High Temperature Oxidation-Resistant Thruster Materials

High Temperature Turbine Blades

Lightweight Structural Foams from Ceramic Materials

Ultramet programs have been featured in the following NASA Tech Briefs: Advanced Materials and Manufacturing for Low-Cost, High-Performance Liquid Rocket Combustion Chambers, January 2013

Lightweight, Ultra-High-Temperature, CMC-Lined Carbon/Carbon Structures, February 2011

Economical Fabrication of Thick-Section Ceramic Matrix Composites, December 2010

Method of Heating a Foam-Based Catalyst Bed, December 2009

Improved Mufflers for General Aviation, January 2009

Rapid Fabrication of Carbide Matrix/Carbon Fiber Composites, September 2007

Modifications of a Composite-Material Combustion Chamber, June 2005

Oxide Protective Coats for Ir/Re Rocket Combustion Chambers, September 2003

Mirror Structures Made of Pyrolytic Graphite, January 2001

Foam Heat Exchangers, April 1999

Progress in the Development of the Regenerated Diesel Engine, August 1996

Medical Design Brief, posted October 2011