Reticulated Vitreous Carbon Foam

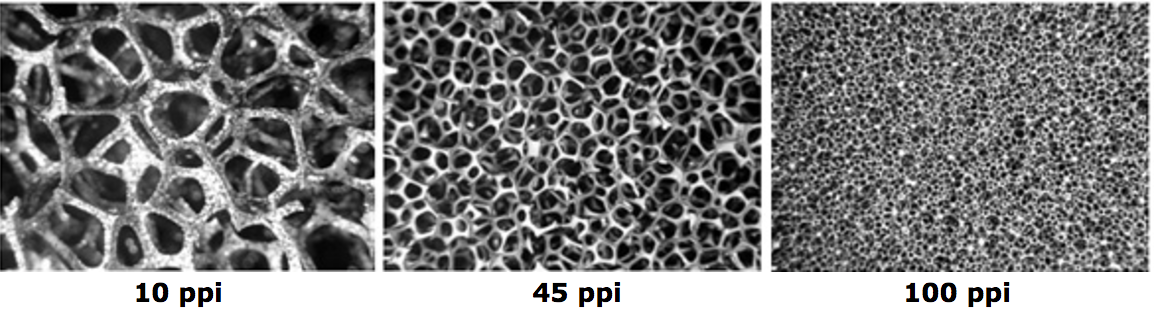

With its patented fabrication process, Ultramet manufactures reticulated vitreous carbon (RVC) foam in a broad variety of shapes and pore sizes. RVC foam has 97% open porosity, low pressure drop, and a three-dimensional cellular structure.

Advantages of RVC

- Extremely low density (0.045 g/cc)

- High surface area

- Thermally insulating

- Electrically conductive

- Easily machinable to near-net-shape

- Stable at high temperatures

- Resistant to thermal shock

- Chemically inert

- Variable pore size

- Low thermal expansion

- Ability to apply thin carbon/carbon facesheets to create lightweight sandwich panels

Applications of RVC

- High temperature insulation

- Filled with aerogel (non-ablating)

- Filled with carbon/phenolic (ablating)

- Cryogenic temperature insulation (filled with aerogel)

- Furnace fixturing and tooling

- Core for lightweight, high stiffness sandwich panel

- Catalyst support

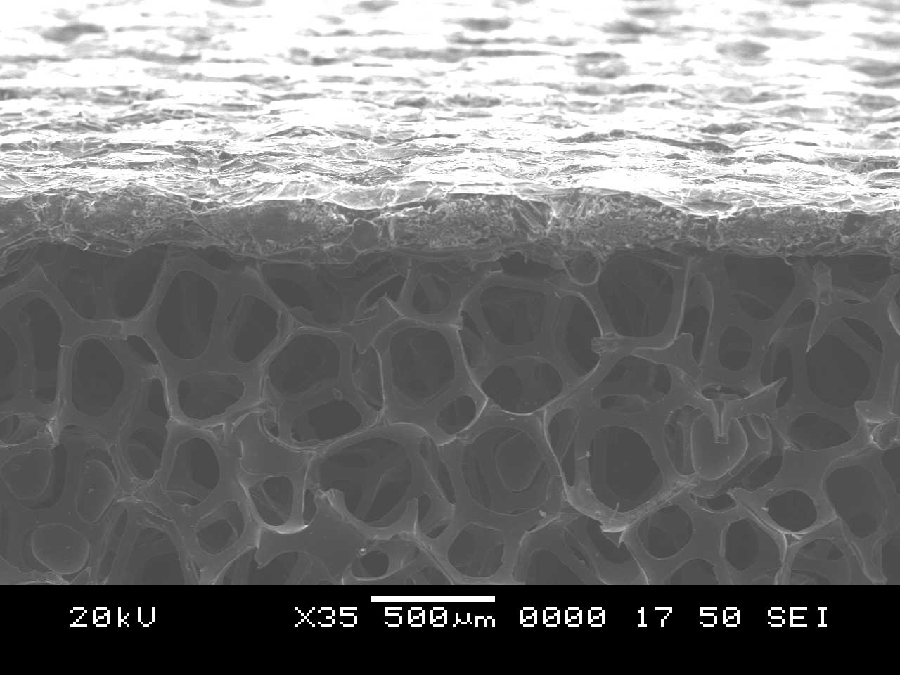

Single-ply C/C facesheet processed directly on surface of RVC foam

Ultramet fabricates RVC foam in pore sizes of 10, 20, 30, 45, 65, 80, and 100 ppi. In addition, Ultramet can fabricate compressed RVC foam, which provides anisotropic properties.

Three samples of RVC foam showing pore structure at different pore sizes (all ~10×)