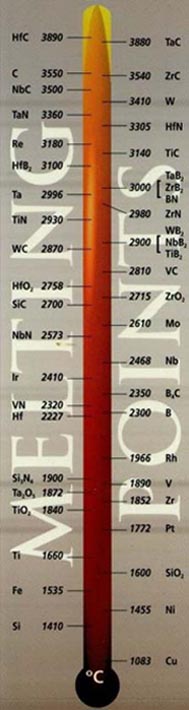

Tungsten, 6165°F (3407°C)

No hydrogen embrittlement

High temperature crystal-growth crucibles

Explosively formed warheads

High temperature furnace elements and heat shields

Rhenium, 5756°F (3180°C)

Ductility, strength at temperature, no hydrogen embrittlement

High-performance rocket engines

In combination with platinum, a reforming catalyst in the production of gasoline

Alloying agent in turbine blade superalloys

Tantalum, 5457°F (3014°C)

Biocompatibility, excellent corrosion resistance

Biomedical implants

Chemical process industry—even thin films of tantalum protect steels and nickel-based alloys against acid attack

High temperature furnaces for the manufacture of capacitors

Molybdenum, 4743°F (2617°C)

No hydrogen embrittlement

Glass-forming industry for melt electrodes

Nozzles for making glass fibers and other items that come in contact with molten glass

Niobium, 4473°F (2467°C)

Less corrosion resistance, lower cost than tantalum

Chemical process industry

High temperature crystal-growth crucibles

| Ruthenium | Osmium |

| Rhodium | Iridium |

| Palladium | Platinum |

Platinum group metals are unique among the transition metals because (except for osmium) they combine excellent catalytic activity with low chemical reactivity. As a result, the platinum group metals at Ultramet are used primarily for two purposes: protective and catalytic coatings.

Iridium and platinum are most frequently used as protective coatings. Platinum generally offers better oxidation resistance than iridium, but iridium has a higher melting point and is thus better suited for higher temperature applications such as rocket engines. Protective coatings must be continuous and free of pores and other defects that would allow the reactive species to reach the underlying material that is being protected.

The morphology of a catalytic coating is different from that of a protective coating. In a catalytic coating, the metal is dispersed onto the substrate as small (10 nm) clusters, and uncoated areas of substrate exist between the clusters. This type of morphology maximizes the surface area of the metal and allows the sides of the clusters, not just the tops, to act as catalytic surfaces.

Platinum group metals are unique among the transition metals because (except for osmium) they combine excellent catalytic activity with low chemical reactivity. As a result, the platinum group metals at Ultramet are used primarily for two purposes: protective and catalytic coatings.

Iridium and platinum are most frequently used as protective coatings. Platinum generally offers better oxidation resistance than iridium, but iridium has a higher melting point and is thus better suited for higher temperature applications such as rocket engines. Protective coatings must be continuous and free of pores and other defects that would allow the reactive species to reach the underlying material that is being protected.

The morphology of a catalytic coating is different from that of a protective coating. In a catalytic coating, the metal is dispersed onto the substrate as small (10 nm) clusters, and uncoated areas of substrate exist between the clusters. This type of morphology maximizes the surface area of the metal and allows the sides of the clusters, not just the tops, to act as catalytic surfaces.

Ceramics are covalent compounds that generally contain metal and nonmetal atoms. Titanium carbide and aluminum oxide are examples of ceramics. Ceramics typically have high melting points, high hardness, excellent chemical corrosion resistance, excellent erosion resistance, and good mechanical properties at elevated temperatures. Some ceramics are good thermal or electrical conductors, whereas others are good insulators or dielectrics.

The brittleness of ceramics leads to their typical use as coatings or reinforcement with fibers. When used as a coating, ceramics provide wear resistance and/or oxidation/corrosion protection. For example, cutting tools can be coated with titanium carbide, which, because of its hardness, results in excellent wear resistance and extended tool life. Graphite components can be coated with silicon carbide to provide oxidation resistance. Other coatings, such as Ultramet’s hafnium carbide/silicon carbide, are customized to provide maximal protection against chemical and oxidative attack at elevated temperatures.

Because ceramics typically have lower densities than refractory metals, interest in replacing heavy, metallic components with ceramics is great. To address the brittleness, ceramics are reinforced with high-strength fibers to provide fracture toughness and minimize brittle behavior. Fiber-reinforced ceramics are most frequently made from silicon carbide because of its low density, high strength, and excellent oxidation/corrosion resistance. For more demanding applications, fiber-reinforced zirconium carbide is used. Ceramics make excellent high temperature filters and catalyst supports because they demonstrate impressive properties at high temperature.