Layered Hafnium Carbide/Silicon Carbide

Hard, wear-resistant, chemically inert, chemically resistant, and nearly impervious to hydrogen at high temperatures, refractory carbides can be formed by chemical vapor deposition at temperatures as low as 10% of their melting point. Ultramet offers the following materials, along with other carbides, nitrides, and silicides:

Advantages

- Higher use temperature than silicon carbide or silicon nitride in an oxidizing environment because a highly stable and protective hafnium silicate forms at the surface

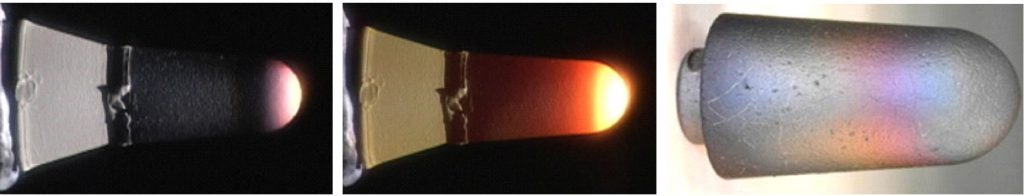

- Survivability demonstrated through hot-gas testing at NASA Ames, NASA Johnson, and Arnold Engineering Development Center

- Protection to 3270°F (1799°C) for extended periods (hours) and to >3800°F (2093°C) for shorter periods

- Zero ablation demonstrated at heat flux levels up to 320 Btu/ft2 · sec (363 W/m2); ablation rate of 0.0002 in/sec (5 µm /sec) was measured at 525 Btu/ft2 · sec (595 W/m2)

- No visible damage in rain erosion testing up to 500 ft/sec relative velocity and 90° angle of attack

- Low thickness required (0.003–0.005″); >0.020″ thickness possible

- High emissivity (0.8–0.85) leads to a 300–500°F (159– 260ºC) reduction in surface temperature relative to alternative ceramics tested at the same heat flux

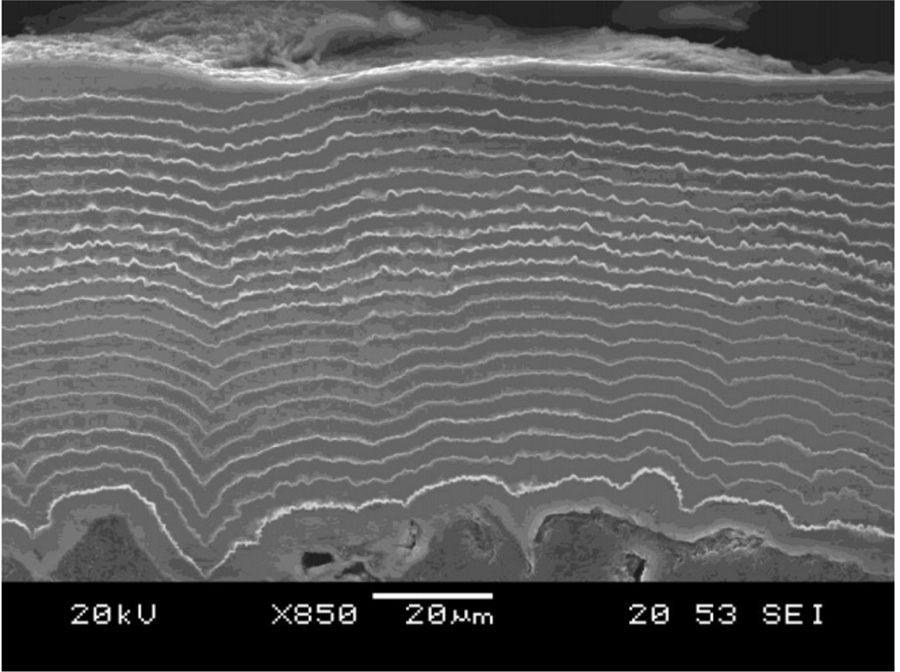

SEM image of polished cross-section of Ultramet HfC/SiC coating (1500×) showing layered structure

Photographs of Ultra2000-coated C/C nosetip during and after 300 second arcjet test performed at NASA Ames Research Center.