Ceramic Matrix Composites : Material Systems

- Cf/ZrC—oxidizing environments from 3200-5000°F

- Cf/HfC—oxidizing environments from 3200-5000°F

- Cf/TaC and Cf/TaC-HfC

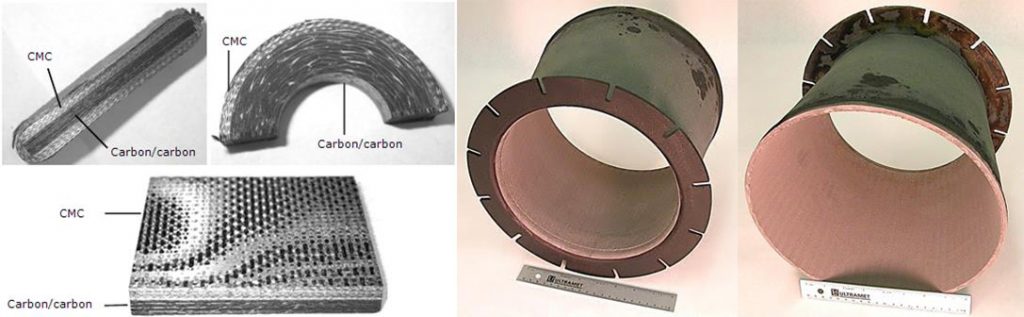

- CMC-encased or CMC-lined carbon/carbon structure

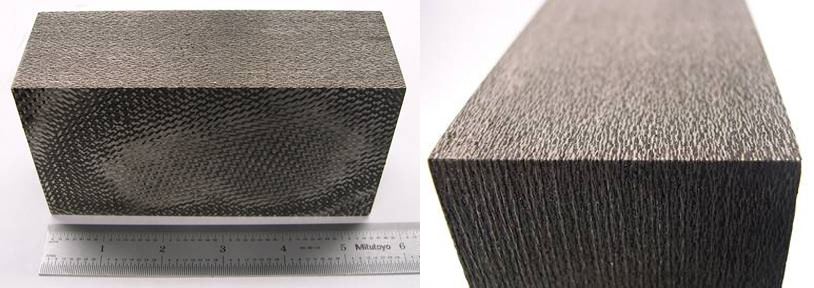

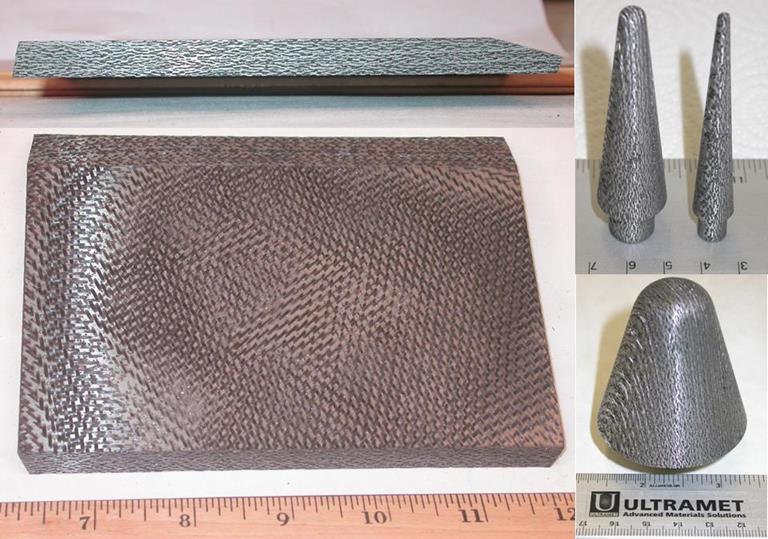

Example of 2.5” thick C/ZrC composite fabricated by melt-infiltration. Panels up to 14” square x 3” thick have been produced

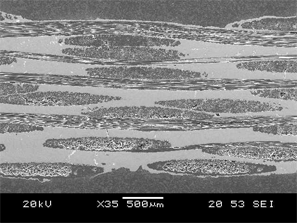

SEM image of two-dimensional orthogonal weave carbon fabric layup reinforcement, illustrating a representative CMC microstructure

CMC-lined carbon/carbon development specimens (left) and carbon/carbon nozzle (right; ID liner; 13” max. dia.) for reduced component weight

Machining the C/ZrC composite with small radius or sharp edges/tips is possible