Ceramic Matrix Composites: Performance

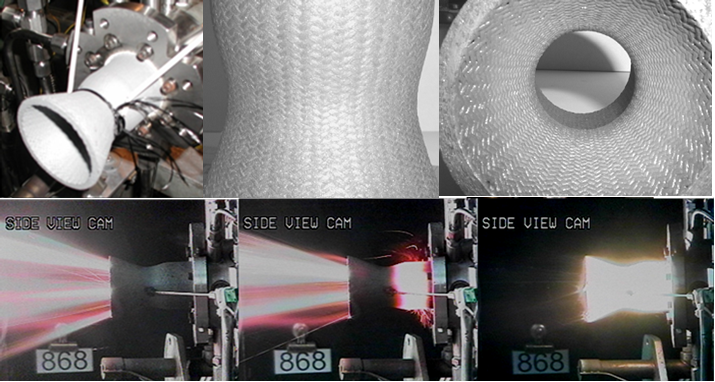

Hot-Fire Test at 4350ºF (2399ºC)

Melt-infiltrated CMC lined carbon/carbon leading edge before

and during arcjet test at NASA Ames Research Center

Melt-infiltrated Cf/ZrC combustion chamber survived multiple 30-second

oxygen/hydrogen hot-fire tests to 4350ºF at NASA Glenn Research Center

Laser Test Up to 5200ºF (2871ºC)

Melt infiltrated Cf/ZrC and Cf/Zr-Si-C composite panels were tested at the Air Force LHMEL-I facility using laser heating and Mach 0.7 airflow.

Weight change was minimal following tests up to 5200F for 300 seconds.

| Material | Duration,sec | Heat Flux W/cm2 | Peak Temperature, F Blackbody Adjusted |

Weight, g Initial Final |

Weight change,g | Weight change/area, g/in2 |

|---|---|---|---|---|---|---|

| C1/Zrc | 300 | 600 | 4858 | ~5200 153.966 | -0.032 | -0.029 |

| C1/Zr-Si-C | 125 | 500 | 4556 | ~4875 170.689 | -0.056 | -0.051 |

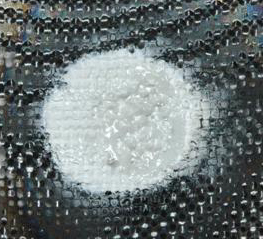

Cf/ZrC

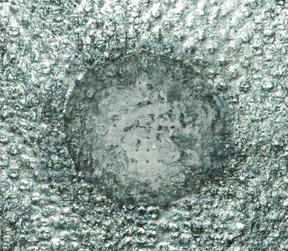

C/Zr-Si-C

Laser spot area on Cf/ZrC (left) and Cf/Zr-Si-C (right) panels after testing at LHMEL