Heat Sinks

Originally developed for cooling wide band gap, high-power radiofrequency amplifier transmit/receive modules, actively cooled heat sinks can also cool laser diodes, traction-insulated gate bipolar transistor modules, and high-power microwave generators. Foam-based heat sinks can also be applied to silicon-based systems by replacing the silicon carbide foam and faceplate with those made from silicon. Regardless of the material used, the actively cooled heat sink can be designed to accommodate high or low coolant flow rates with minimal pressure drop.

Water and air have each been used as the coolant, but virtually any fluid can be used. Because silicon carbide is extremely resistant to oxidation and corrosion, compatibility between the coolant and the foam is not a concern.

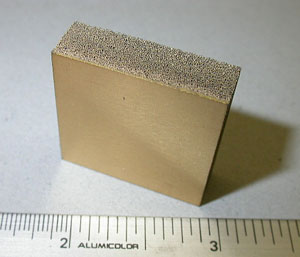

Ultramet fabricates foam heat sinks up to 12″ × 12″.

Silicon carbide foam heat sink with silicon carbide faceplate used as a heat spreader