Thermal Protection System

Aerogel-filled Foam Insulation

Ultramet fills an open-cell foam skeleton with ultralow-density aerogel to create a highly insulating and lightweight foam-core thermal protection material that can be economically fabricated into large and complex shapes.

Benefits

- Low density (0.07 g/cm3 or 4.4 lb/ft3)

- High-temperature capability (4500°F [2482°C])

- Low thermal conductivity (<1 W/m·K at 3600°F)

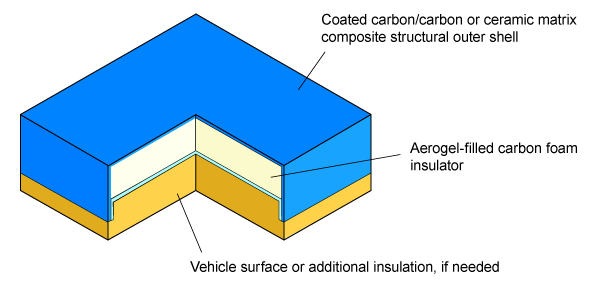

- Ability to combine with ceramic matrix composite or coated carbon/carbon structural shells to produce an integrated airframe/insulator thermal protection systems

- Foam can be press-fit over complex shapes

Applications of Thermal Protection System

- Hypersonic vehicles (engine and airframe)

- Aerobraking structures for planetary exploration

- Launch vehicle propulsion systems

- Gas turbine and ramjet/scramjet engine components

- Furnace heat recovery units (recuperators)

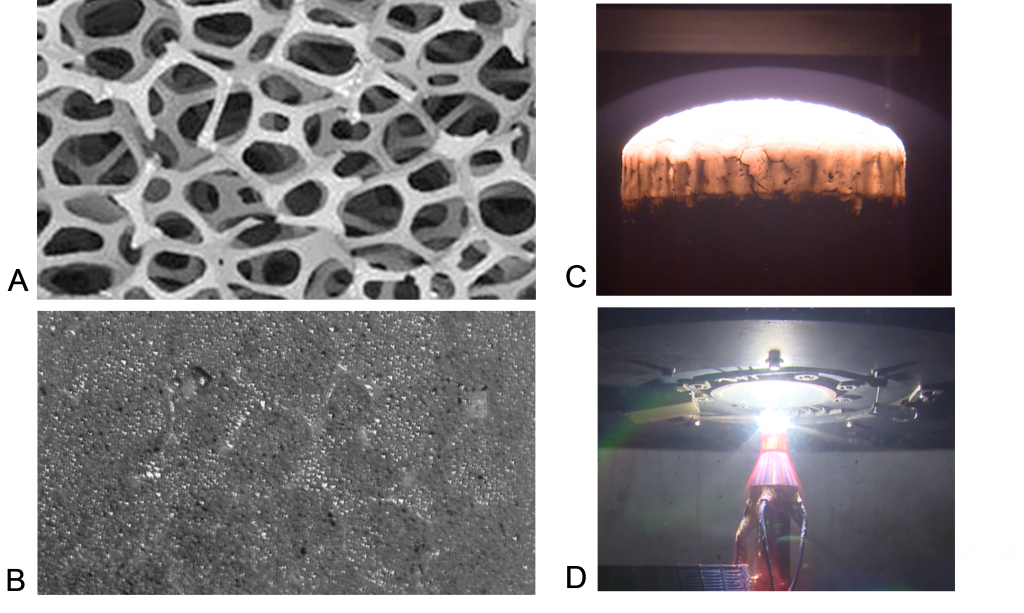

Aerogel-filled carbon foam TPS panel during 243 second radiant heat test (foam contained within 1″ thick carbon/carbon box)(3500°F hot face, 350°F back face at shutdown

Thin structural shell containing aerogel-filled foam core

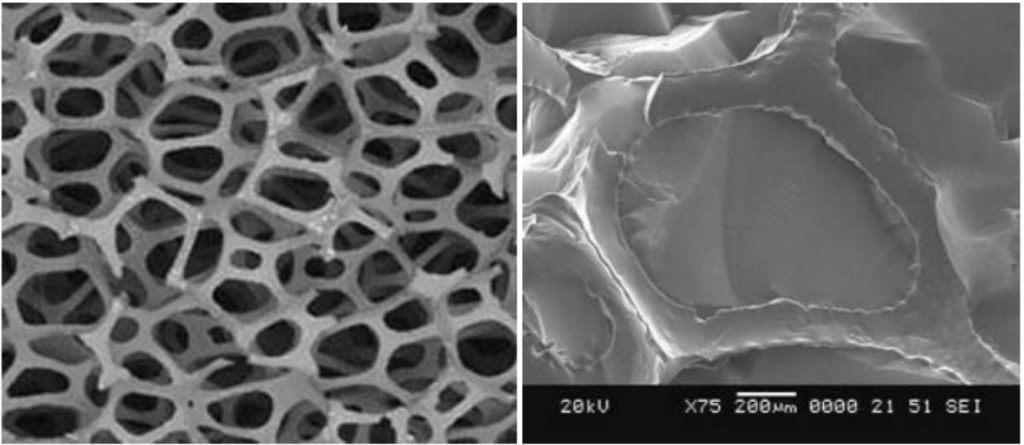

The carbon foam serves as an easily machinable structural reinforcement for the low strength aerogel insulator and defines the shape of the component. This approach can also be used with oxide foam and aerogel materials.

The combined density of the foam/aerogel composite insulator is just under 0.07 g/cm3 and has a use temperature approaching 4000°F (2204°C). This combination of materials is effective because although the foam support is highly insulating, the transfer of heat by radiation through the pores dominates at high temperatures, and the carbon aerogel filler minimizes this transfer.

In the foam/aerogel composite, the aerogel exists in discrete cells that are supported by the foam skeleton, so the low structural integrity inherent to aerogels does not impede production of large monolithic structures.

Unfilled 97% porous carbon foam skeletal structure before aerogel infiltration (left) and single foam cell after complete infiltration with carbon aerogel (right)

Produced from commercially available polyurethane foam, the carbon foam skeleton is inherently economical. A cost-effective air drying process allows rapid fabrication of aerogel-filled foam structures in large sizes with properties that are comparable with those generated during conventional processes.

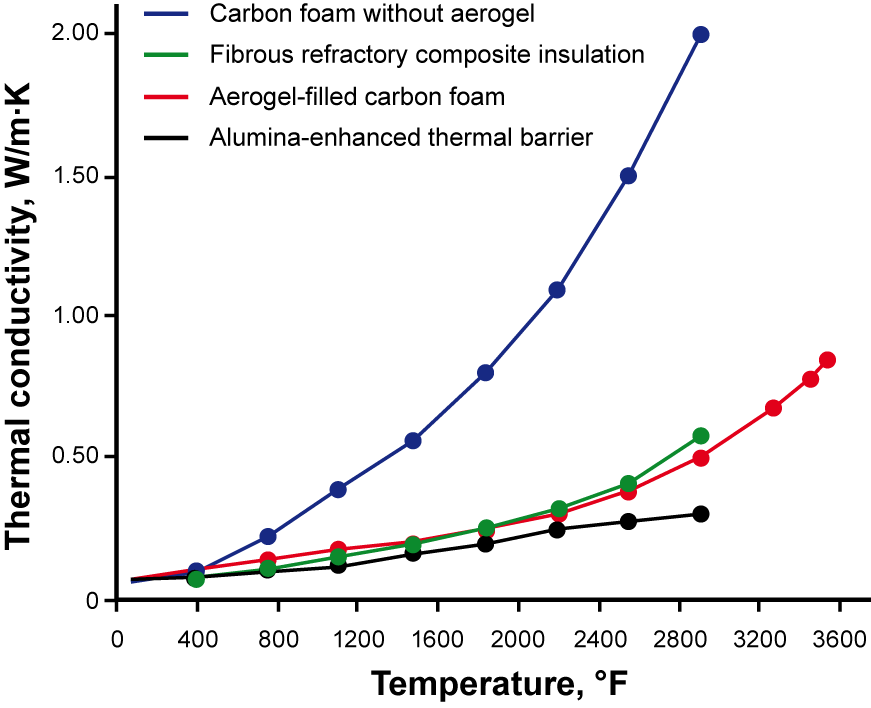

The thermal conductivity of unfilled carbon foam increases rapidly with temperature as radiation through the 97% porous structure becomes the dominant mode of heat transfer. Fibrous refractory composite insulation was a moderate temperature space shuttle insulator that had a low conductivity of 0.6 W/m·K at 2900°F (1593°C). The conductivities of aerogel-filled carbon foam and alumina-enhanced thermal barrier tile are even lower at 0.5 and 0.3 W/m·K, respectively. In addition to the benefit of increased use temperature, the foam/aerogel insulator offers a substantial weight advantage. The density of the alumina-enhanced thermal barrier tile used on the space shuttle was 0.19 g/cm3 (12 lb/ft3), whereas the density of the foam/aerogel insulator is just 0.07 g/cm3 (4.4 lb/ft3).

Ablator-Filled Foam Insulation

For high heat flux applications such as heat shields and nozzle liners, carbon/phenolic ablators are infiltrated into open-cell carbon foam. Relative to conventional ablators, foam-reinforcement foam reinforcement enhances surface char layer retention and reduces erosion and heat transfer. Density is variable from 40-80 lb/ft3.

Open-cell carbon foam before (A) and after (B) infiltration with phenolic/chopped fiber ablator and typical specimen during NASA ARC arcjet test (up to 2203 W/cm2 heat flux) (C-D)