Refractory Open-Cell Foams: Carbon, Ceramic, and Metal

Refractory foams are a new class of open-cell, low density materials that Ultramet has developed to produce lightweight porous structures for aerospace and industrial applications.

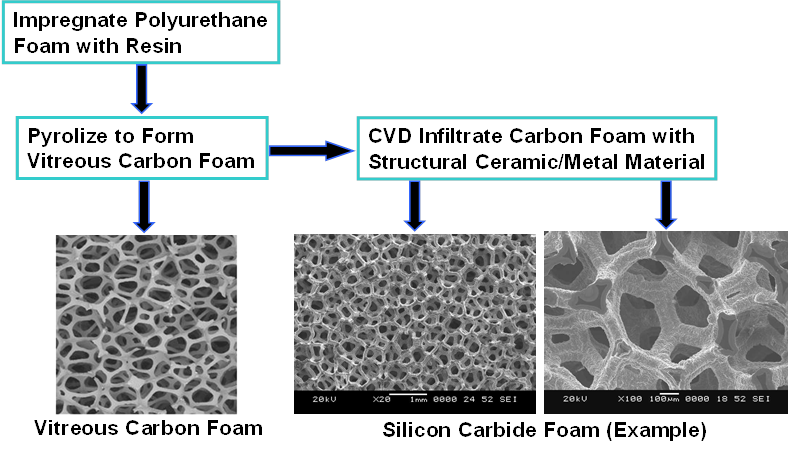

Fabrication of Refractory Open-Cell Foam

Ultramet pyrolyzes a polymer foam to create a reticulated vitreous carbon foam that has unique physical, thermal, and electric properties. Refractory metals and ceramics can then be infiltrated into the foam to tailor the material properties for specific applications.

Impregnate polyurethane foam of desired pore size with resin